Quest’s Engineering Team has the ability to engineer, design, and build facilities in the upstream and midstream oil and gas sectors and beyond. Whether it’s customized engineering or using standard facility designs based on our industry knowledge and experience, we have a solution for you. Quest Engineering plays a key role in Procurement and Project Management, setting the standard for completion of projects.

Engineering Solutions

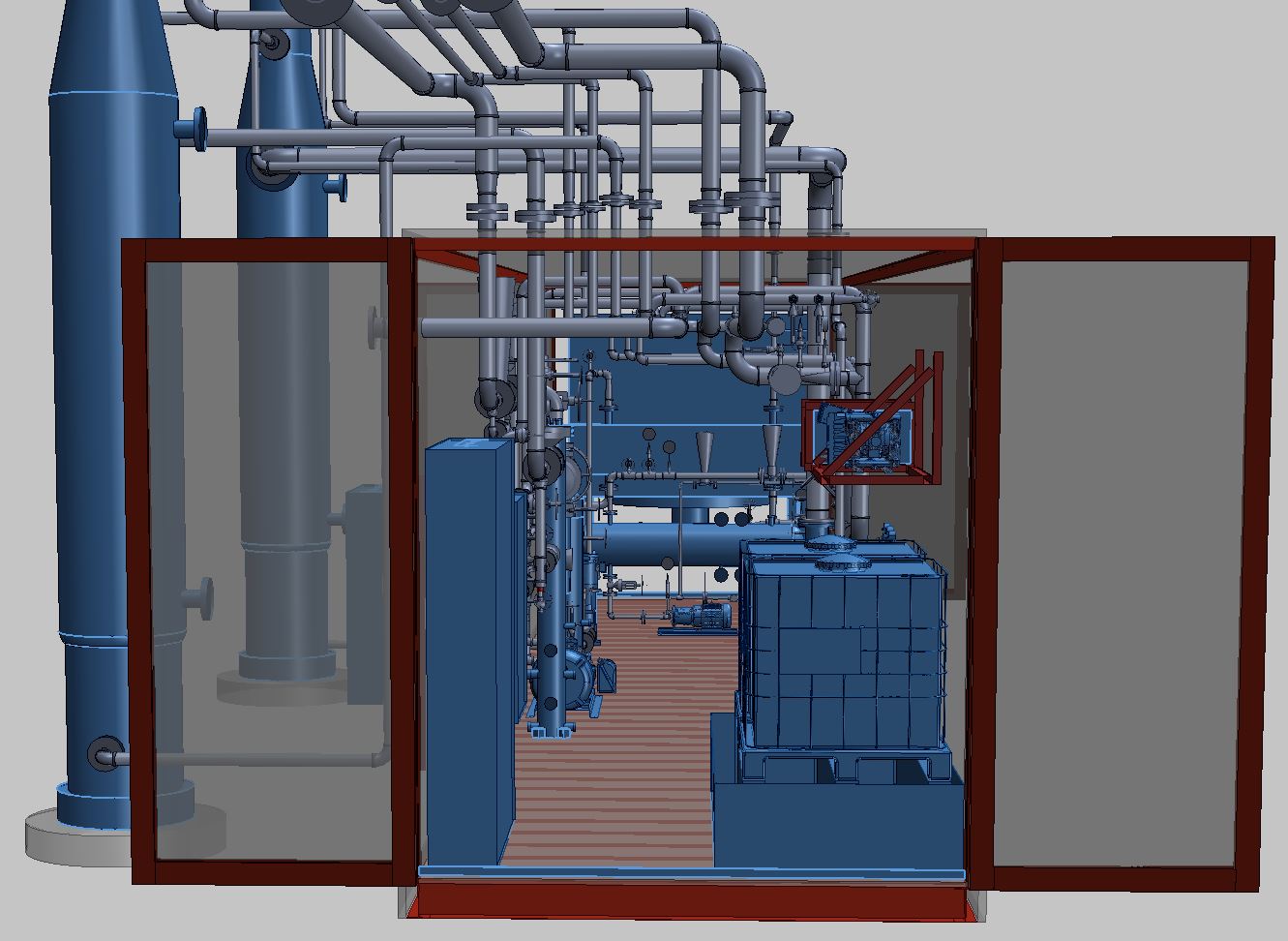

- Detailed Drawings (Includes GeneralLayout, Plot Plan, P&ID, 3D Model and Design, HYSYS Simulation)

- Laser Scanning

- Cryogenic NGL Plant

- RJT Plants

- Temperature Swing Adsorption (TSA) also known as Molecular Sieve Dehydration System

- Hot Oil Systems + Waste Heat Recovery Systems

- Propane (or other) Refrigeration Systems

- Instrument/utility Air systems

- Turbine Compression

- Reciprocating Compression

- Flare/Vent/Blowdown Relief Systems

- Amine Units

- Glycol Units

- Stabilizer Units

- Pumping Systems

- Slug Catching Systems

- Salt Water Disposal Systems (SWDs) – Water Reinjection Systems

- Central Processing Facilities (CPFs) -Well Pad oil/water/gas separation and processing

- Pressure Vessels

- Tank Storage

- Flare Design

- Instrument Air

- Skids

- Pump Systems

- Piping and Valving

- Control Valves

From time to time, depending on the project details and staffing requirements, Quest EPC, LLC may provide certain engineering services including mechanical, electrical and chemical engineering services directly or may provide those services by utilizing third party engineers.